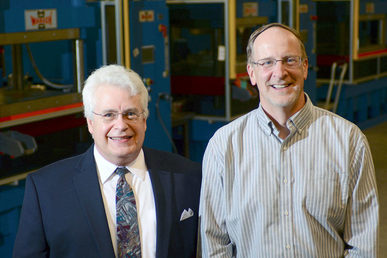

Bob Larsen (left) and David Walter (right) Bob Larsen (left) and David Walter (right) PORT ANGELES, WA - Wednesday, July 26, 2017 -After launching the world’s first facility to recycle uncured carbon fiber composite into new consumer products and bringing new jobs and technology to Port Angeles, Composite Recycling Technology Center (CRTC) CEO Bob Larsen is retiring. Larsen will leave the post on Aug. 11. He will be replaced by Chief Operating Officer David Walter, who will combine his current role with that of CEO. “Bob has put his heart and soul into making the CRTC successful – from finding start-up funding and bringing in research projects and partners, to setting up the facility, building the team and producing our first product,” Walter said. “He is leaving the CRTC in good shape and with everything we need to move forward and be successful.” Larsen has served as CEO since March 2016. Prior to that he was chairman of the CRTC’s Board of Directors. He was instrumental in establishing strategic partnerships with Toray Composite Materials America, ELG Carbon Fibre, Ltd., and the Institute for Advanced Composite Manufacturing Innovation (IACMI) to create new markets for recycled carbon fiber materials left over from aerospace manufacturing. “Starting up the CRTC and bringing new jobs and economic development to Port Angeles has been a very gratifying experience, and I have been honored to be able to serve our community,” Larsen said. “But I realized, when my wife and I went on our ‘bucket list’ vacation to Europe recently, that there are a lot of things we want to do together that I don’t have time to do with my current responsibilities. The CRTC is very well positioned for future success and I look forward to cheering them on.” From its new, state-of-the-art facility leased from the Port of Port Angeles, the CRTC has pioneered the recycling and reuse of tons of uncured carbon fiber composite scrap that would otherwise go to landfills. The CRTC’s focus is to create jobs and drive economic development in Clallam County. The U.S. produces about 29 million pounds of carbon fiber scrap per year, with 2 million pounds per year produced in Washington state – a volume expected to double over the next five to eight years, with the expansion of regional manufacturing. Under a new contract with IACMI, the CRTC will pioneer ways to automate processing of this scrap and remanufacture it into new consumer products. This technology breakthrough is essential so carbon fiber scrap can be processed in high volumes, fulfilling the enormous potential for energy savings and carbon reduction and creating a global composites recycling industry. For its technological innovation and new market creation, CRTC earned the Silver Award for Sustainability from Seattle Business Magazine in 2017. The company has created 16 jobs and more than $3 million in new economic activity over the past year, garnering a 2016 Award of Excellence from the Clallam County Economic Development Corporation. The CRTC has a multi-faceted agreement with Toray Composite Materials America for scrap carbon fiber supply and materials development, and continues to work very collaboratively with this strategic partner. Funding for the CRTC recycling facility and campus was provided by the Port of Port Angeles, the U.S. Economic Development Administration, the Washington State Department of Commerce, the Clallam County Opportunity Fund and the City of Port Angeles. The CRTC campus also houses Peninsula College’s Advanced Manufacturing Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. ###

0 Comments

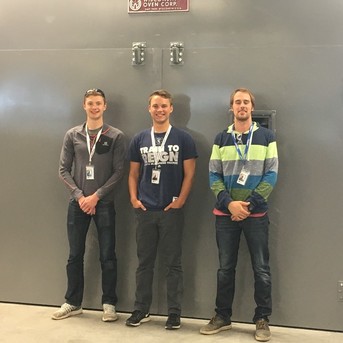

Back Row, left to right: Cliff Eberle, Uday Vaidya PhD, Soydan Ozcan, Geoffrey Wood. Front Row, Left to right: Dr. Sharon Buck, Robin Pate, Joannie Harmon Heath, Robert Larsen Back Row, left to right: Cliff Eberle, Uday Vaidya PhD, Soydan Ozcan, Geoffrey Wood. Front Row, Left to right: Dr. Sharon Buck, Robin Pate, Joannie Harmon Heath, Robert Larsen PORT ANGELES, WA – In 2016, the Composite Recycling Technology Center (CRTC) became the first facility in the world to transform carbon fiber composite pre-preg scrap into new products. Now, thanks to a new contract with a national manufacturing institute, the CRTC will pioneer ways to automate processing of this scrap. This technology breakthrough is essential so recycled carbon fiber (rCF) can be processed in high volumes fulfilling its enormous potential for energy savings and carbon reduction and creating a global composites recycling industry. The one-year contract with the Institute for Advanced Composite Manufacturing Innovation (IACMI) will provide over $400,000 for the CRTC’s work to design and build processing equipment designed specifically to prepare uncured aerospace carbon fiber scrap for high volume manufacturing applications. The CRTC plans to begin making products using this process by the end of 2017 and quadruple the throughput of scrap material by the middle of 2018. The novel manufacturing machinery developed under this contract will be instrumental in growing the number and volume of products made at the CRTC. Moreover, the technology developed by the CRTC will be made available to other facilities seeking to recycle composites in high volume, boosting the emergence of this new industry. This contract announcement further cements the CRTC/IACMI partnership announced one year ago at a celebratory MOU signing event featuring leadership from the two partnering organizations, The Department of Energy’s Advanced Manufacturing Office, Washington’s Department of Commerce, the Port of Port Angeles, and local economic development groups. “The IACMI contract is a landmark achievement,” said the CRTC’s CEO Bob Larsen. “It validates the CRTC’s technology approach from the national level and is a strong vote of confidence in our young company and its business plans. It supports our drive to self-sufficiency and for creating good-paying local jobs and advances the growth of the carbon fiber recycling industry, a core part of the CRTC’s and IACMI’s missions.” IACMI-The Composites Institute is one of over ten national Manufacturing Innovation Institutes that accelerate U.S. advanced manufacturing by supporting research and development of new technologies, production processes, and workforce training opportunities via shared contributions from the public and private sectors. IACMI’s focus on advancing composite material technology includes a significant effort in recycling of composite materials – a sizable challenge constraining the growth of the industry. Washington Senator Maria Cantwell, a longtime champion of CRTC, had this to say about the agreement: “Washington state and the Composite Recycling Technology Center are continuing to lead the way on carbon fiber recycling technology. These are the types of public-private partnerships we should be investing in to grow good paying manufacturing jobs.” “Technical innovation is a major driver of Washington state’s economy and it’s happening everywhere, not just Seattle,” said Commerce Director Brian Bonlender. “Our Clean Energy Fund is one way in which we invest to strengthen rural communities by cultivating new business opportunities and jobs for the low-carbon future. The Port Angeles CRTC leveraged state and local funding to attract national and international attention and additional investment that is advancing their world-leading work to produce new high-volume, low-cost products out of scrap aerospace carbon fiber.” The contract also includes planning support from the CRTC for IACMI’s recycled composites program. The CRTC will be working closely with IACMI’s Materials and Processing researchers from Oak Ridge National Laboratory and the University of Tennessee, Knoxville throughout the contract. The technical targets of this project will provide the building blocks for future programs in higher-throughput advanced rCF equipment development, leading to the use of repurposed carbon composite scrap in vehicles and clean energy production applications within 5 years. The CRTC, an independent 501(c)(3) non-profit corporation, was launched by the Port of Port Angeles in 2015 as an economic development initiative to respond to the growing need of the composite and aerospace industries to recycle and reuse remnants from their production processes. It is the only company in the world to divert uncured carbon fiber scrap from landfills and transform it into consumer products. The CRTC moved into a new production facility on 18th Street in Port Angeles in August, 2016, and currently employs 17 people. 2018 projections point to more than doubling the number of employees by the end of next year. The CRTC has a supply and technical support agreement with Toray Composites America, and a multi-faceted agreement with ELG Carbon Fibre for joint recycled carbon fiber supply as well as rCF material and product development. The CRTC’s campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. This program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with the CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. For more information about the CRTC, see www.compositerecycling.org. For more information about IACMI-The Composites Institute, visit www.iacmi.org. FOR IMMEDIATE RELEASE. For more information, contact: Bob Larsen, 360-819-1202 #####  Left to right; David Kennedy, Wesley Houser, Jacob Icard in front of the CRTC's Wisconsin Oven Left to right; David Kennedy, Wesley Houser, Jacob Icard in front of the CRTC's Wisconsin Oven Port Angeles, WA—June 5, 2017—The Composite Recycling Technology Center (CRTC) based in Port Angeles, WA has brought three Engineering Interns on board for the summer. With all the projects that the CRTC has in motion right now, hiring key engineering talent is critical to helping the company get products developed and out to the market quickly. The CRTC welcomes the following Interns to the team: · David Kennedy – Port Angeles, WA – entering his junior year in mechanical engineering at the University of Idaho · Wesley Houser – Bainbridge, Island, WA - entering his junior year in mechanical engineering at Gonzaga University · Jake Icard – Kingston, WA - entering his senior year in mechanical engineering at the University of Hawaii. For additional information: CRTC Contact: David Walter ([email protected]), COO, 1-360-819-1203 Port Angeles, WA—June 05, 2017—The Composite Recycling Technology Center (CRTC) based in Port Angeles, WA has begun creating jobs in production. Effective June 1, Jamie Trowbridge, a ten-year resident of Port Angeles, WA, will move into the CRTC’s first full-time production position. Jamie brings to the CRTC a wealth of experience in aerospace composites manufacturing. Jamie had been unemployed for quite some time, and was unable to find a position that fit his skill level. While unemployed, Jamie chose to dedicate his full attention to his family and fledgling small gaming company, D6 Studios. Jamie was first introduced to the CRTC when he came in on a Saturday to help produce 150 demo paddles that Chief Operations Officer Dave Walter was taking to the USAPA Nationals pickleball tournament in Arizona. To date, Jamie has made nearly 400 paddles and is thrilled to be earning a family wage and receiving the comprehensive benefits that the CRTC offers. What Jamie likes most about working at the CRTC is the company’s core values, that everyone is easy to get along with, and that he feels he has a voice and can make a difference. Plus, he gets to work with state of the art equipment and be on the cutting edge of composites recycling. AeroPaddles is now producing the Swift 2.0 paddle which will soon be coming out with three new color variations. The paddles can be purchased through Pickle Ball Central based out of Kent, WA. For additional information: CRTC Contact: David Walter ([email protected]), COO, 1-360-819-1203 PORT ANGELES – In the first 5 months of its operation, the Composite Recycling Technology Center (CRTC) has earned the Silver Award for Sustainability from Seattle Business Magazine. A total of 16 awards were made to pioneering Washington manufacturing companies at an awards ceremony Wednesday evening at the Museum of Flight that attracted business leaders from across the state. |

| “We are delighted to receive this prestigious award from Seattle Business Magazine for our first product,” said Bob Larsen, CRTC CEO. “If the business community loved our first product, wait until they see the other products we have in our pipeline,” he added. “We are readying a raft of products for the industrial, consumer, and public markets, with several due to be launched before the end of the year. We’re gunning for the Gold Sustainability award for 2018!” The award program was supported by presenting sponsor Chase Commercial Banking and signature sponsors Moss Adams and Impact Washington. |

The CRTC, an independent 501(c)(3) non-profit corporation, was launched by the Port of Port Angeles as an economic development initiative to respond to the growing need of the composite and aerospace industries to recycle and reuse remnants from their production processes.

The CRTC is the only facility in the world to divert uncured carbon fiber composite scrap from landfills and transform it into consumer products. It moved into a new production facility on 18th Street in Port Angeles in August, 2016. The CRTC production process using recycled carbon fiber uses only 10 percent of the energy needed for like products made from virgin carbon fiber.

About 29 million pounds of carbon fiber composite scrap ends up in U.S. landfills every year -- 2 million pounds of that is produced in Washington state, which is a volume expected to double over the next five to eight years, with the expansion of regional manufacturing.

The CRTC has a supply and technical support agreement with Toray Composites America, and a multi-faceted agreement with ELG Carbon Fibre for joint recycled carbon fiber supply, and materials and product development.

Funding for the CRTC, its new recycling facility, and production equipment was provided by the Port of Port Angeles, the U.S. Economic Development Administration, the Washington State Department of Commerce, and the Clallam County Opportunity Fund, with the City of Port Angeles providing significant in-kind support.

The CRTC campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations.

For more information, see www.compositerecycling.org.

#####

Composite Recycling Technology Center Signs Memorandum of Understanding with ELG Carbon Fiber

3/14/2017

Collaboration on Carbon Fiber Recycling will help advance the composites industry

Port Angeles, WA—March 10, 2017—The Composite Recycling Technology Center (CRTC) based in Port Angeles, WA and ELG Carbon Fibre Ltd (ELG) based in Coseley, UK, announce that they have signed a Memorandum of Understanding to collaborate on carbon fiber recycling.

Under the terms of the agreement, the CRTC and ELG will develop innovative ways to utilize the carbon fiber that gets reclaimed by ELG’s state of the art pyrolysis process, and turn it into value added products that positively impact people’s lives and our environment.

“We are thrilled and honored to be working with an outstanding company like ELG. Their industry-leading recycling process and technical know-how allows for them to recover carbon fiber from cured materials at a very competitive price. We see opportunities to combine their recovered carbon fiber with our repurposed carbon fiber pre-preg to produce a wide range of value-added products. In addition, the CRTC is interested in manufacturing products from ELG’s blend of recycled carbon fiber and thermoplastics. This high-performance, low-cost material opens up significant doors for collaboration on multiple product applications” said David Walter, Chief Operating Officer of the CRTC.

“We are very excited about the opportunity to work closely with the CRTC and are already discussing some major projects that will kick-start the recycled carbon fiber industry on an international level. Our fiber and resins combined with their research, product development expertise, and production capabilities are an excellent match that will lead to multiple innovations” said Frazer Barnes, Managing Director of ELG.

“Today’s announcement represents a major milestone for the CRTC,” said Robert Larsen, CEO of the CRTC. “Working closely with ELG means that we can provide a one-stop carbon fiber recycling team that addresses the needs of large-scale generators of carbon fiber scrap. It also provides the CRTC with a consistent supply of low-cost recycled carbon fiber and thermoplastics. When combined with our recycled carbon fiber pre-preg, it will create dozens of beneficial uses for this previously landfilled material. We believe this partnership creates significant opportunities for high volume production of cost-competitive components for automotive and Clean Energy applications. Our product development efforts and subsequent manufacturing initiatives will create living wage jobs for our community and will reap significant additional economic, energy, and environmental benefits.”

For additional information:

CRTC Contact: David Walter ([email protected]), COO, 1-360-819-1203

ELG Contact: Frazer Barnes ([email protected]), Managing Director, +011 44 (1902) 406010

About ELG Carbon Fibre Ltd. (ELG):

ELG Carbon Fibre Ltd. are the pioneers of sustainable CFRP recycling. Our UK site is based in the West Midlands and our global expansion plans include the launch of additional overseas facilities. Our goal is to help business avoid the unnecessary cost of disposing of their scrap waste and end-of-life carbon fibre composites to land-fill or incineration plants. These have both a cash and environmental cost. ELG Carbon Fibre offer a range of high quality recycled carbon fibre products at competitive prices in forms that are readily usable in a number of industrial applications. Please visit our website at www.elg.de/en/home for more information.

About the Composite Recycling Technology Center (CRTC):

Founded in September 2015, the Composite Recycling Technology Center (CRTC) is an innovative independent 501(c)(3) non-profit corporation, whose mission is to inspire and grow the global composite recycling community through innovation in technology and manufacturing, that transforms carbon fiber scrap into products that positively impact people’s lives and our environment. Since carbon fiber is stronger than steel at one third the weight, the product applications in segments like transportation, aerospace and high performance sporting goods are boundless. The CRTC is accomplishing its mission by providing direct product manufacturing and technical design services, as well as by making low-cost recycled carbon fiber feedstock available for other manufacturers to utilize.

The CRTC is supported through commitments from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration, WA State’s Clean Energy Fund, Clallam County, and the City of Port Angeles. Find out more at www.compositerecycling.org

The CRTC campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with the CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. Learn more at www.pencol.edu/composites

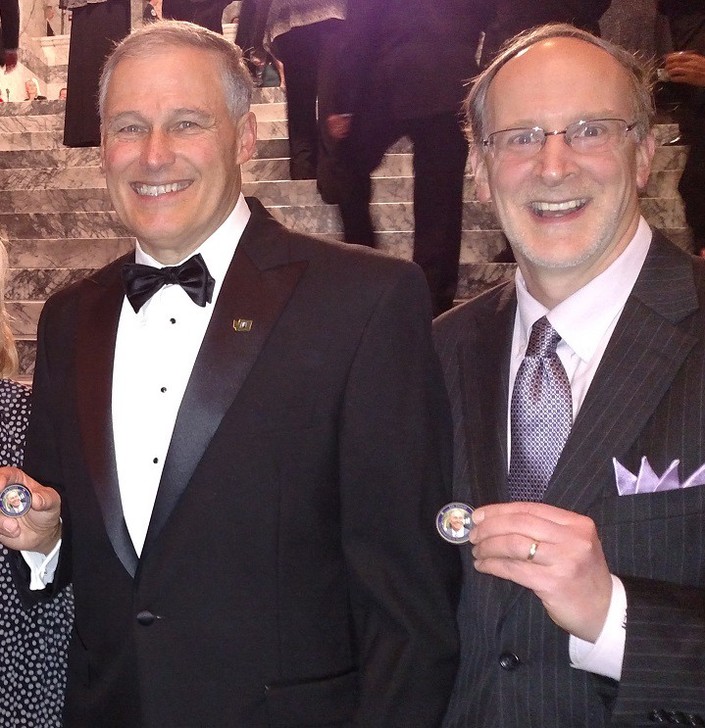

The Composite Recycling Technology Center created about 2,300 commemorative coins for Gov. Jay Inslee’s inauguration last week. (Jesse Major/Peninsula Daily News)

PORT ANGELES — The Composite Recycling Technology Center created about 2,300 commemorative coins for Gov. Jay Inslee’s inauguration last week. The coins, made of 16 layers of recycled aerospace-quality carbon fiber, were a gift to the state from the CRTC, said Bob Larsen, its CEO.

On one side of the coin is a photo of Inslee. The other side features the state. “It was another first for Washington state and Port Angeles that we were able to produce something like this for the governor’s inauguration,” he said. “It’s a high-tech example of the ability of this material to be shaped and formed to most anything.”

Larsen said the state reached out to the CRTC in November. Over the course of one day, CRTC officials decided it was possible to produce the coins. Now, officials hope to make similar products the CRTC could sell, he said.

“This concept has been so well-received, we’re actually thinking about something similar to this and turning it into a product we could customize for people,” he said. Larsen also plans to make similar coins with CRTC branding that can be handed out during trade shows.

The state previously gave the CRTC a $1.7 million grant that was matched by the Port of Port Angeles over 2015, 2016 and 2017.

Inslee was at the groundbreaking for the CRTC in 2015.

“We’re grateful to the state for believing in us and investing in us,” Larsen said. “This is another example of how we’re leveraging local and state money to attract even more resources.”

________

Reporter Jesse Major can be reached at 360-452-2345, ext. 56250, or at jmajor@peninsula dailynews.com.

PORT ANGELES — The Composite Recycling Technology Center created about 2,300 commemorative coins for Gov. Jay Inslee’s inauguration last week. The coins, made of 16 layers of recycled aerospace-quality carbon fiber, were a gift to the state from the CRTC, said Bob Larsen, its CEO.

On one side of the coin is a photo of Inslee. The other side features the state. “It was another first for Washington state and Port Angeles that we were able to produce something like this for the governor’s inauguration,” he said. “It’s a high-tech example of the ability of this material to be shaped and formed to most anything.”

Larsen said the state reached out to the CRTC in November. Over the course of one day, CRTC officials decided it was possible to produce the coins. Now, officials hope to make similar products the CRTC could sell, he said.

“This concept has been so well-received, we’re actually thinking about something similar to this and turning it into a product we could customize for people,” he said. Larsen also plans to make similar coins with CRTC branding that can be handed out during trade shows.

The state previously gave the CRTC a $1.7 million grant that was matched by the Port of Port Angeles over 2015, 2016 and 2017.

Inslee was at the groundbreaking for the CRTC in 2015.

“We’re grateful to the state for believing in us and investing in us,” Larsen said. “This is another example of how we’re leveraging local and state money to attract even more resources.”

________

Reporter Jesse Major can be reached at 360-452-2345, ext. 56250, or at jmajor@peninsula dailynews.com.

Visitors to Gov. Jay Inslee’s office Wednesday received a special token of appreciation when they dropped by for a public open house following his inaugural address.You can’t spend these tokens, but they are worth a lot to our state.

Inaugural carbon fiber tokens, produced by the Composite Recycling Technology Center in Port Angeles, Wash. (Official Governor’s Office Photo)Produced in Port Angeles from aerospace carbon fiber composite scrap diverted from landfills, these little discs help showcase how Washington state is leading the world in developing innovative green technology that is both good for the environment and the economy.

The Composite Recycling Technology Center (CRTC) in Port Angeles is the first facility in the world to transform uncured carbon fiber composite scrap into new products. CRTC is pioneering manufacturing processes that will make it easier to recycle and create high-performance, low-cost products from this material.

The tokens are truly a statewide effort. They were produced through a partnership among five Washington State manufacturers:

• Composite Recycling Technology Center, Port Angeles

• Toray Composites America, Tacoma

• Flow Waterjet Americas, Kent

• Players Technical, Bellingham

• ProGraphics, Bellingham

The recipient of two Washington State Clean Energy Fund awards, CRTC has also received funding from the Port of Port Angeles, Clallam County and the U.S. Economic Development Administration. Toray Composites America provides the carbon fiber composite scrap material.

Gov. Jay Inslee and David Walter, COO, Composite Recycling Technology Center at the Inaugural Ball with the Inaugural Tokens. These commemorative inauguration tokens — and other products being developed at CRTC — are proof that strong public-private partnerships in clean technology can create huge impact for Washington.

Original Post

PORT ANGELES – Aero Paddles, dba The Composite Recycling Technology Center (CRTC) has announced that it has signed an exclusive distribution agreement with Pickleball Central, to distribute the very first pickleball paddle made with recycled aerospace grade carbon fiber. Aero Paddles expect to launch the paddle in the first quarter of 2017 under the model name of SWIFT.

The game of Pickleball was invented on Bainbridge Island, Washington in 1965 and is now the fastest growing sport in North America with approximately 3 million players globally. With the paddles from Aero Paddles being manufactured at CRTC’s headquarters in Port Angeles, WA and with Pickleball Central, headquartered in Kent, WA, the new Paddle has a total Washington State connection.

Pickleball is a sport played on a badminton-sized court with the net lowered to 34 inches at the center. It is played with a perforated plastic ball similar to a whiffle ball and composite or wooden paddles about twice the size of ping-pong paddles. It can be played indoors or outdoors and is easy for beginners to learn, but can develop into a fast-paced, competitive game for experienced players. In addition, the game has developed a passionate following due to its friendly, social nature, and its multi-generational appeal.

“We are extremely pleased to be able to work with the market leader in pickleball distribution in Pickleball Central. Their knowledge around the sport and the service that they provide their customers is world class” said David Walter, CRTC COO.

“With carbon fiber being much lighter than aluminum but even stronger than steel, it is a perfect fit for a high-performance sporting good like a pickleball paddle. We are very excited about launching our first product into such an exciting and rapidly growing sport as pickleball” said Bob Larsen, CRTC CEO.

“Pickleball Central has enjoyed explosive growth and we are very pleased to be able to bring the SWIFT paddle to the market. The feedback from the initial trials has been extremely positive and we very excited to get this paddle out for our customers to enjoy” said David Johnson, Co-founder of Pickleball Central.

For additional information:

Contact: David Walter (mailto:[email protected]), COO, (360) 477-1560

Contact: David Johnson (mailto: [email protected]), Co-founder, (253) 236-3821

About Aero Paddles and the Composite Recycling Technology Center (CRTC):

The CRTC is an innovative non-profit company founded in 2015 whose mission is to lead and grow a composite recycling industry that diverts carbon fiber scrap destined for landfills, and turns it into value-added products. Since carbon fiber is stronger than steel with significantly lower weight (up to 75% less) the product applications in segments like transportation, clean tech and high performance sporting goods are boundless. The CRTC will accomplish its mission through direct product manufacturing and by providing research and development to advance the recycled composites industry. The CRTC is supported through commitments from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration, WA State’s Clean Energy Fund, Clallam County, and City of Port Angeles. Find out more at www.compositerecycling.org

The CRTC, an independent 501(c)(3) non-profit corporation, was launched by the Port of Port Angeles as an economic development initiative to respond to the growing need of the composite and aerospace industries to recycle and reuse remnants from their production processes.

The CRTC campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations.

NEWS RELEASE: Washington State’s Composite Recycling Technology Center wins $500K “Innovation Accelerator” grant, debuts first retail product at Museum of Flight

About Pickleball Central:

Pickleball Central was recently acknowledged by the Puget Sound Business Journal as one of "Washington State's 100 Fastest-Growing Private Companies". They operate the world's largest online pickleball equipment retail store specializing in paddles, balls, nets, and court supplies. Ranked # 1 in customer service for racquet sports retailers, Pickleball Central is a family oriented, privately held company operating in Kent, Washington. The company was founded in 2006 and has served over 100,000 customers worldwide. Find out more at www.pickleballcentral.com.

The game of Pickleball was invented on Bainbridge Island, Washington in 1965 and is now the fastest growing sport in North America with approximately 3 million players globally. With the paddles from Aero Paddles being manufactured at CRTC’s headquarters in Port Angeles, WA and with Pickleball Central, headquartered in Kent, WA, the new Paddle has a total Washington State connection.

Pickleball is a sport played on a badminton-sized court with the net lowered to 34 inches at the center. It is played with a perforated plastic ball similar to a whiffle ball and composite or wooden paddles about twice the size of ping-pong paddles. It can be played indoors or outdoors and is easy for beginners to learn, but can develop into a fast-paced, competitive game for experienced players. In addition, the game has developed a passionate following due to its friendly, social nature, and its multi-generational appeal.

“We are extremely pleased to be able to work with the market leader in pickleball distribution in Pickleball Central. Their knowledge around the sport and the service that they provide their customers is world class” said David Walter, CRTC COO.

“With carbon fiber being much lighter than aluminum but even stronger than steel, it is a perfect fit for a high-performance sporting good like a pickleball paddle. We are very excited about launching our first product into such an exciting and rapidly growing sport as pickleball” said Bob Larsen, CRTC CEO.

“Pickleball Central has enjoyed explosive growth and we are very pleased to be able to bring the SWIFT paddle to the market. The feedback from the initial trials has been extremely positive and we very excited to get this paddle out for our customers to enjoy” said David Johnson, Co-founder of Pickleball Central.

For additional information:

Contact: David Walter (mailto:[email protected]), COO, (360) 477-1560

Contact: David Johnson (mailto: [email protected]), Co-founder, (253) 236-3821

About Aero Paddles and the Composite Recycling Technology Center (CRTC):

The CRTC is an innovative non-profit company founded in 2015 whose mission is to lead and grow a composite recycling industry that diverts carbon fiber scrap destined for landfills, and turns it into value-added products. Since carbon fiber is stronger than steel with significantly lower weight (up to 75% less) the product applications in segments like transportation, clean tech and high performance sporting goods are boundless. The CRTC will accomplish its mission through direct product manufacturing and by providing research and development to advance the recycled composites industry. The CRTC is supported through commitments from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration, WA State’s Clean Energy Fund, Clallam County, and City of Port Angeles. Find out more at www.compositerecycling.org

The CRTC, an independent 501(c)(3) non-profit corporation, was launched by the Port of Port Angeles as an economic development initiative to respond to the growing need of the composite and aerospace industries to recycle and reuse remnants from their production processes.

The CRTC campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations.

NEWS RELEASE: Washington State’s Composite Recycling Technology Center wins $500K “Innovation Accelerator” grant, debuts first retail product at Museum of Flight

About Pickleball Central:

Pickleball Central was recently acknowledged by the Puget Sound Business Journal as one of "Washington State's 100 Fastest-Growing Private Companies". They operate the world's largest online pickleball equipment retail store specializing in paddles, balls, nets, and court supplies. Ranked # 1 in customer service for racquet sports retailers, Pickleball Central is a family oriented, privately held company operating in Kent, Washington. The company was founded in 2006 and has served over 100,000 customers worldwide. Find out more at www.pickleballcentral.com.

SEATTLE, Wash. – Many times stronger than steel and less than half the weight of aluminum, carbon fiber composite scrap – once considered worthless – took center stage today in a press conference with a twist, hosted by the Washington State Department of Commerce at the Museum of Flight.

U.S. Assistant Secretary of Commerce for Economic Development Jay Williams announced a $500,000 i6 Challenge grant to the Composite Recycling Technology Center (CRTC) of Port Angeles, Clallam County. Funding is part of the Regional Innovation Strategies (RIS) program, an initiative to spur innovation capacity-building activities in regions across the nation.

Following brief remarks, a portable net was unfurled and Williams and CRTC CEO Robert Larsen each grabbed pickleball paddles made from carbon fiber composite scrap and faced off with a whiffle ball.

The friendly game heralded another important milestone for the CRTC: the quiet, lightweight pickleball paddles manufactured there are the world’s first retail product produced from uncured carbon fiber (also known as “pre-preg”) composite scrap. (Pickleball, invented in 1965 by former state Congressman Joel Pritchard on Bainbridge Island, is one of the fastest growing sports in North America with over three million players globally.)

“The Port Angeles Composite Recycling Technology Center is revolutionizing advanced manufacturing while creating jobs locally,” said Assistant Secretary Williams. “As America’s Innovation Agency, the U.S. Department of Commerce plays a key role in supporting the entrepreneurs and job creators of tomorrow. Congratulations to CRTC on receiving the RIS award and for their contributions in workforce training programs, building infrastructure and promoting innovation here in Washington State.”

“Making Pickleball paddles out of carbon fiber composite isn’t new – but making them out of scrap carbon fiber composite is groundbreaking. That’s because - until now - no one has been able to prove there is value in scrap aerospace carbon fiber composite. It has been considered worthless, and that’s why 29 million pounds of it ends up in our country’s landfills every year. But today, CRTC is proving to the world that recycling it doesn’t just make good environmental sense, it makes good business sense,” said Robert Larsen, CEO of the Composite Recycling Technology Center.

“Bold innovation is found in every corner of Washington state, not just our high-tech research and development centers around Seattle,” said Commerce Director Brian Bonlender. “CRTC’s work is proving that it’s possible to both grow the economy and protect the environment. The Clean Energy Fund is proud to be among the numerous public and private partners committed to bringing world-leading clean tech manufacturing jobs to the peninsula. Together we are strengthening this community for the future.”

The Washington State Clean Energy Fund has invested $2.7 million in the CRTC’s work to develop and manufacture clean technology products and reduce waste from composite manufacturing. Even though today’s advanced carbon fiber composite is used for many high performance items, from automobiles, airplanes and boat hulls to wind turbine blades, safety clothing and fishing rods, an estimated 29 million pounds of scrap ends up in U.S. landfills each year because the material has been considered too difficult to recycle and there is no proven market for it.

CRTC is changing that.

A Clean Energy Fund matching grant announced in September helped to purchase advanced waterjet equipment made in Kent, WA from Flow Corporation. CRTC will use it when serial manufacturing and shipping of their revolutionary SWIFT Aero Paddles begins in January.

The Port of Port Angeles has been instrumental in launching the CRTC, investing $3.3 million to match the state’s grants and enabling the CRTC to get on its feet. U.S. Senator Maria Cantwell and U.S. Representative Derek Kilmer have consistently supported the CRTC and its mission. The center has accumulated over $5 million in local, state, federal and private funding since its formation in 2015.

“This first-ever recycled carbon fiber composite product is a major milestone for the Port of Port Angeles and the Carbon Recycling Technology Center. Today’s announcement of the $500,000 Innovation Accelerator grant will push CRTC to new heights and demonstrates their innovation is a strong, economic driver that creates new, good-paying jobs,” said Sen. Maria Cantwell.

“This is all about jobs and economic opportunity for our region, and that's why I lent my support to this grant application. Securing these funds is great news for the future of advanced manufacturing in Port Angeles,” said Representative Derek Kilmer. “Our composite recycling center, one of the first in the nation, is already showing that the Peninsula can be a hub for groundbreaking innovation. Now, this national investment will give entrepreneurs the tools they need to take yesterday’s recycled parts and turn them into advanced products. It will also encourage the growth of quality jobs in our region by giving local people the skills they need to build a career working with composites.”

Public and private partners in the successful Innovation Accelerator proposal include Peninsula College, Profile Composites, Altair Engineering, the Jamestown S’Klallam Tribe, Impact Washington, and the Composites Washington Consortium.

In addition, Toray Composites America is providing the scrap material. The company is key to an Institute for Advanced Composites Manufacturing Innovation (IACMI) research and development project with Janicki industries and Globe Manufacturing, to produce lightweight automotive structural parts.

###

Contact: Penny Thomas, Commerce Press Office, (206) 256-6106

U.S. Assistant Secretary of Commerce for Economic Development Jay Williams announced a $500,000 i6 Challenge grant to the Composite Recycling Technology Center (CRTC) of Port Angeles, Clallam County. Funding is part of the Regional Innovation Strategies (RIS) program, an initiative to spur innovation capacity-building activities in regions across the nation.

Following brief remarks, a portable net was unfurled and Williams and CRTC CEO Robert Larsen each grabbed pickleball paddles made from carbon fiber composite scrap and faced off with a whiffle ball.

The friendly game heralded another important milestone for the CRTC: the quiet, lightweight pickleball paddles manufactured there are the world’s first retail product produced from uncured carbon fiber (also known as “pre-preg”) composite scrap. (Pickleball, invented in 1965 by former state Congressman Joel Pritchard on Bainbridge Island, is one of the fastest growing sports in North America with over three million players globally.)

“The Port Angeles Composite Recycling Technology Center is revolutionizing advanced manufacturing while creating jobs locally,” said Assistant Secretary Williams. “As America’s Innovation Agency, the U.S. Department of Commerce plays a key role in supporting the entrepreneurs and job creators of tomorrow. Congratulations to CRTC on receiving the RIS award and for their contributions in workforce training programs, building infrastructure and promoting innovation here in Washington State.”

“Making Pickleball paddles out of carbon fiber composite isn’t new – but making them out of scrap carbon fiber composite is groundbreaking. That’s because - until now - no one has been able to prove there is value in scrap aerospace carbon fiber composite. It has been considered worthless, and that’s why 29 million pounds of it ends up in our country’s landfills every year. But today, CRTC is proving to the world that recycling it doesn’t just make good environmental sense, it makes good business sense,” said Robert Larsen, CEO of the Composite Recycling Technology Center.

“Bold innovation is found in every corner of Washington state, not just our high-tech research and development centers around Seattle,” said Commerce Director Brian Bonlender. “CRTC’s work is proving that it’s possible to both grow the economy and protect the environment. The Clean Energy Fund is proud to be among the numerous public and private partners committed to bringing world-leading clean tech manufacturing jobs to the peninsula. Together we are strengthening this community for the future.”

The Washington State Clean Energy Fund has invested $2.7 million in the CRTC’s work to develop and manufacture clean technology products and reduce waste from composite manufacturing. Even though today’s advanced carbon fiber composite is used for many high performance items, from automobiles, airplanes and boat hulls to wind turbine blades, safety clothing and fishing rods, an estimated 29 million pounds of scrap ends up in U.S. landfills each year because the material has been considered too difficult to recycle and there is no proven market for it.

CRTC is changing that.

A Clean Energy Fund matching grant announced in September helped to purchase advanced waterjet equipment made in Kent, WA from Flow Corporation. CRTC will use it when serial manufacturing and shipping of their revolutionary SWIFT Aero Paddles begins in January.

The Port of Port Angeles has been instrumental in launching the CRTC, investing $3.3 million to match the state’s grants and enabling the CRTC to get on its feet. U.S. Senator Maria Cantwell and U.S. Representative Derek Kilmer have consistently supported the CRTC and its mission. The center has accumulated over $5 million in local, state, federal and private funding since its formation in 2015.

“This first-ever recycled carbon fiber composite product is a major milestone for the Port of Port Angeles and the Carbon Recycling Technology Center. Today’s announcement of the $500,000 Innovation Accelerator grant will push CRTC to new heights and demonstrates their innovation is a strong, economic driver that creates new, good-paying jobs,” said Sen. Maria Cantwell.

“This is all about jobs and economic opportunity for our region, and that's why I lent my support to this grant application. Securing these funds is great news for the future of advanced manufacturing in Port Angeles,” said Representative Derek Kilmer. “Our composite recycling center, one of the first in the nation, is already showing that the Peninsula can be a hub for groundbreaking innovation. Now, this national investment will give entrepreneurs the tools they need to take yesterday’s recycled parts and turn them into advanced products. It will also encourage the growth of quality jobs in our region by giving local people the skills they need to build a career working with composites.”

Public and private partners in the successful Innovation Accelerator proposal include Peninsula College, Profile Composites, Altair Engineering, the Jamestown S’Klallam Tribe, Impact Washington, and the Composites Washington Consortium.

In addition, Toray Composites America is providing the scrap material. The company is key to an Institute for Advanced Composites Manufacturing Innovation (IACMI) research and development project with Janicki industries and Globe Manufacturing, to produce lightweight automotive structural parts.

###

Contact: Penny Thomas, Commerce Press Office, (206) 256-6106

RSS Feed

RSS Feed