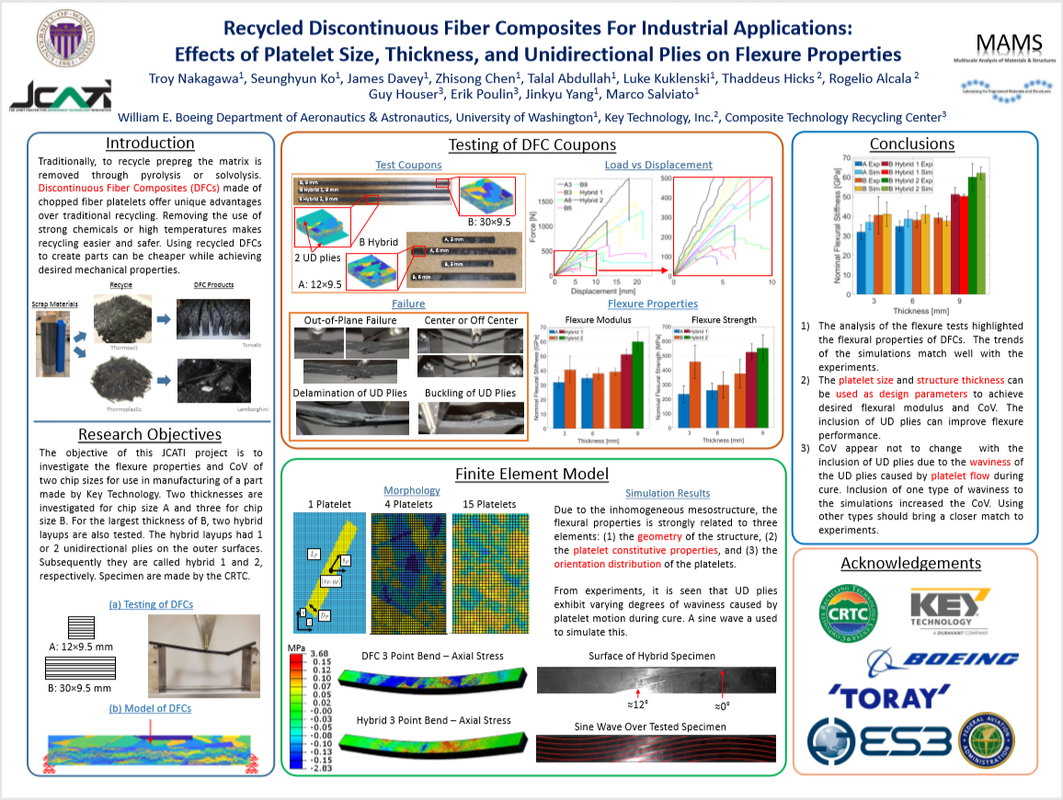

University of washington presents modeling analysis research using crtc chopped carbon fiber samples4/12/2021 We're excited to share this modeling analysis that University of Washington performed using chopped carbon fiber composite samples provided by the CRTC. This research is being shared today, April 12th, at the JCATI (Joint Center for Aerospace Technology Innovation) Virtual Symposium today. Use this link to view a short video about their findings:

https://drive.google.com/file/d/120JKu2OdfNDQmREtlDHamui4j0oZ8o9l/view

0 Comments

Thank You To Author: Brian Mittege, AWB (Photos/Video: Brian Mittege/AWB)

Friday, October 5th was the second day of Association of Washington Business (AWB)'s cross-state Manufacturing Week 2018 Bus Tour and the day started in Port Angeles with a visit to the new Composite Recycling Technology Center. The facility, which shares space with Peninsula College, turns scrap aerospace carbon fiber into new products including park benches and skateboards. Students at the school can earn degrees and certificates in advanced manufacturing and composites. The nonprofit, research-drive CRTC aims to divert some of the 50 million pounds of composite material that goes into landfills globally each year, CEO David Walter told the AWB tour members and several local leaders who joined the tour at the Port Angeles stop. "That's a beautiful material -- space-age, aerospace-grade scrap," Walter said. Among the wide-ranging ideas CRTC is exploring for recycled composites: creating a composite wood/carbon fiber I-beam that is both strong and light. Among the 17 employees at CRTC is Amber Hartman, who said she appreciates being part of a manufacturer that is helping solve environmental problems. "I love it," she said about her job on the production floor, where she was helping make recycled carbon fiber components for a portable Pickleball court. From there, the bus headed south toward the Port Townsend Paper Company. The Kraft paper mill, which is the largest private employer in Jefferson County and one of the largest recyclers in the state, was idle for a scheduled maintenance but AWB’s team was able to tour the facility along with state Reps. Mike Chapman and Steve Tharinger. Also joining the tour for that stop was Brian Kuh, executive director for the Economic Development Council of Jefferson County. The motto of Port Townsend Paper Corp.: "We are local people sustainably making international products since 1927."The bus rolled south down the Olympic Peninsula in the afternoon and met up with Walmart’s Debbie Herron at the Walmart in Shelton. Several “Refresh Stops” are planned throughout the tour at Walmart locations around the state. AWB Vice President Gary Chandler spoke to a group of managers at the Shelton Walmart, describing how AWB's push to support Washington-made goods fits with Walmart's $250 billion commitment to sell more made-in-America items on its shelves. With the crew refreshed and ready to go, the bus ventured up a steep, muddy logging road on Green Diamond Resources land near Shelton. State Sen. Tim Sheldon, along with state Reps. Mike Chapman and Drew MacEwan, formed an informal bipartisan delegation for the trip and a discussion that touched on Green Diamond's century-plus history in Mason County under five generations of family ownership. The day ended with a tour through one of the newest and biggest mills in the country, the Sierra Pacific Industries mill in Shelton. The company recently finished a $100 million investment to completely rebuild and revamp the property, which has been home to a timber mill in one form or another since 1890. Unlike old days, where 30 percent or more of a log would be wasted, the new mill finds uses for every part of the log as its proprietary computerized systems quickly analyze, sort, mill and process 180 log trucks worth of logs a day. "Virtually every flake is used for something," said Lisa Perry of Sierra Pacific Industries. For more information https://www.awb.org/manufacturing-week/ The SwiftNet™ is light, simple and sets up fast

KENT, WASHINGTON, June 21, 2018 – Pickleball Central and the Composite Recycling Technology Center today announced availability of a unique new portable pickleball net system that will revolutionize one of the fastest growing sports in the world. The SwiftNet™ will transform the experience of setting up a pickleball net, making pickleball more accessible to players around the world. The new net system uses a patent pending design to radically change how quickly and easily a pickleball court can be set up. Released under the Pickle-Ball, Inc. brand, the SwiftNet™ addresses all the major concerns the pickleball community has had with prior portable net systems. The new system is easier to transport, easier to setup, more durable, and provides players with a better on-court experience. US OPEN and USAPA Nationals Gold Medalist Glen Peterson remarks, “this net is revolutionary – it weighs half the weight, sets up in less than half the time, and recreates the quality of play of the world’s highest end permanent court systems.” Pickleball is a rapidly growing sport with over 3 million players in the U.S. and the sport continues to grow significantly on a global basis. Municipal, scholastic, and private athletic facilities are addressing the growing population by creating spaces within their venues for pickleball play. The portable SwiftNet™ is a breakthrough solution to this fast-growing sport, allowing players and institutions to quickly set up tournament caliber courts in as little as 180 seconds. These innovative nets are sustainably made using recycled aerospace grade carbon fiber, making them about half the weight of other portable net systems available. With its unique carbon fiber boom and pole design, the SwiftNet™ can be setup by one person, in under three minutes. The main structure will not bend or rust, and is much stronger and more durable than competing products. The SwiftNet™ portable net system provides the stiffness similar to a tournament net with a much simpler tensioning mechanism, and automatically sets and holds a true 36” and 34” height. All the structural and carbon fiber components are made and assembled in Port Angeles, Washington. David Walter, CEO of the CRTC, said “The CRTC is honored to have worked closely with Pickleball Central on the development and launch of this excellent product into the market. We believe customers will appreciate how quickly the lightweight system sets up and how it responds like a tournament net. It is an excellent offering that is helping to keep scrap carbon fiber out of landfills, creating jobs, and giving our customers far more places to play this rapidly growing sport.” Edward Hechter, CEO of Pickleball Central, stated “Our goal is to serve the ever growing community of pickleball players, coaches, ambassadors, and tournament directors. In our 12-year history, we’ve never found a product that is as revolutionary to the sport as this one. It will make the sport more accessible, and provide a better on-court experience. Partnership with the amazing team at CRTC to produce this net system has been so rewarding, knowing that we are producing a world-class product right here in Washington state.” With a manufacturer’s suggested retail price of $349, the SwiftNet™ Pickleball Net can be ordered online at Pickleball Central. About Pickleball Central Pickleball Central is the largest pickleball company in the world. They operate the world's largest online pickleball equipment retail store specializing in paddles, balls, nets, and court supplies. They also produce the Pickleball, Inc. brand of nets, balls, and paddles. Ranked # 1 in customer service for racquet sports retailers by Trust Pilot, Pickleball Central is a family oriented, privately held company operating in Kent, Washington. The company was founded in 2006 and has served over 100,000 customers worldwide. Find out more at www.pickleballcentral.com and www.pickleball.com About the Composite Recycling Technology Center (CRTC) Founded in September 2015, the Composite Recycling Technology Center (CRTC) is an innovative independent 501(c)(3) non-profit corporation, whose mission is to inspire and grow the global composite recycling community through innovation in technology and manufacturing, that transforms carbon fiber scrap into products that positively impact people’s lives and our environment. Since carbon fiber is stronger than steel at one third the weight, the product applications in segments like transportation, aerospace and high-performance sporting goods are boundless. The CRTC is accomplishing its mission by providing direct product manufacturing and technical design services, as well as by making low-cost recycled carbon fiber feedstock available for other manufacturers to utilize. The CRTC is supported through commitments from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration (EDA), a grant from the EDA i6 Regional Innovation Strategies Program (RIS), WA State’s Clean Energy Fund, Clallam County, and the City of Port Angeles. Find out more at www.compositerecycling.org/. For additional information Pickleball Central contact: Karen Thomas, Director of Marketing [email protected] - (253)243-9853 22330 68th Ave South, Kent, Washington, 98032 CRTC contact: Leslie Perkins, Marketing Manager [email protected] - (619) 302-4942 2220 West 18th Street, Port Angeles, WA 98363  PORT ANGELES, WASHINGTON, April 30, 2018 - Attendees of the Washington Recreation and Park Association (WRPA) annual tradeshow in Seattle will get to experience the world’s first park bench made with recycled aerospace grade carbon fiber featured by the Composite Recycling Technology Center (CRTC), located in booth #20. May 1st through 3rd, representatives from the recreation and park industry have a great opportunity to look up close, feel, and sit on the Olympus Bench in person, so they can envision this amazing product in their space. The City of Port Angeles Washington will be the first to purchase these benches to replace all of its wooden benches in public parks, through a new Adopt-A-Bench program to defray costs. Each bench has a unique ceramic plaque built into the back that can display color and graphics, making it a great outreach tool for local businesses that want to use a bench for advertisement. The plaque will also serve as a great way to memorialize a loved one or to recognize a community hero. “We are very excited about the Adopt-A-Bench program and are delighted with the CRTC bench,” said Corey Delikat, Parks & Recreation Director for the City of Port Angeles. “It is a beautiful and functional piece of art that is going to look great in all of our parks and recreation areas.” The innovative benches were designed by Robert Stokes, who served as the Consulting Designer and Artist on the project. The CRTC just launched this new bench model and began taking orders in April. Interest is growing as this bench differentiates itself from other benches with many exceptional features:

The durability of the Olympus Bench makes it an outstanding value for public agencies looking for a modern attractive bench choice that is easy to maintain with a much longer lifespan, for use at parks, transit stops, or other outdoor and indoor public areas. “We are honored and excited to show the Olympic Bench to the parks and recreation professionals at the WRPA Annual Conference in Seattle and to share the innovation story behind the Olympus bench,” shared Dave Walter, Chief Executive Officer at CRTC. To learn more about purchasing a bench and to receive a quote, please visit the CRTC’s website at www.compositerecycling.org/bench. For additional information: Composite Recycling Technology Center contact: Leslie Perkins at (619) 302-4942 or [email protected] About the Composite Recycling Technology Center (CRTC): Founded in September 2015, the Composite Recycling Technology Center (CRTC) is an innovative independent 501(c)(3) non-profit corporation, whose mission is to inspire and grow the global composite recycling community through innovation in technology and manufacturing, that transforms carbon fiber scrap into products that positively impact people’s lives and our environment. Since carbon fiber is stronger than steel at one third the weight, the product applications in segments like transportation, aerospace and high performance sporting goods are boundless. The CRTC is accomplishing its mission by providing direct product manufacturing and technical design services, as well as by making low-cost recycled carbon fiber feedstock available for other manufacturers to utilize. The CRTC is supported through commitments from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration (EDA), a grant from the EDA i6 Regional Innovation Strategies Program (RIS), WA State’s Clean Energy Fund, Clallam County, and the City of Port Angeles. Find out more at www.compositerecycling.org The CRTC campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with the CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. Learn more at www.pencol.edu/composites CRTC Launches the World’s First Park Bench Made With Recycled Aerospace Grade Carbon Fiber3/12/2018  Port Angeles, WA—March 12, 2018 - The Composite Recycling Technology Center is now taking orders for the world’s first park bench made from recycled aerospace grade carbon fiber. These benches are light and extremely strong. They do not rot, are impervious to insect damage, are easy to clean and will look great year after year, even in tough marine environments that degrade other outdoor seating. The benches’ durability makes them an outstanding value for public agencies looking for much longer replacement cycles for benches in parks, at transit stops, or other outdoor and indoor public areas. The City of Port Angeles Washington will be the first to purchase these benches to replace all of its wooden benches in public parks, through a new Adopt-A-Bench program to defray costs. Each bench has a unique ceramic plaque built into the back that can display color and graphics, making it a great outreach tool for local businesses that want to use a bench for advertisement. The plaque will also serve as a great way to memorialize a loved one or to recognize a community hero. “We are very excited about the Adopt-A-Bench program and are delighted with the CRTC bench,” said Corey Delikat, Parks & Recreation Director for the City of Port Angeles. “It is a beautiful and functional piece of art that is going to look great in all of our parks and recreation areas.” The innovative benches were designed by Robert Stokes, who served as the Consulting Designer and Artist on the project. “Carbon fiber is such an outstanding material and makes the bench so strong and light. We really believe this has the opportunity to revolutionize the parks and recreation space,” said David Walter, CEO of the CRTC. “Using recycled, aerospace-grade carbon fiber doubles the benefit for the environment.” Those interested in purchasing a bench or learning more about the offering can visit the CRTC’s website at www.compositerecycling.org/bench. The MSRP is $4,500 per bench, with volume discounts available. Those interested in the Adopt-A-Bench program with the City of Port Angeles can contact the City at 360-417-4523 or at [email protected]. For additional information: Composite Recycling Technology Center contact: Emily Dexter at (360) 819-1204 or [email protected] About the Composite Recycling Technology Center (CRTC): Founded in September 2015, the Composite Recycling Technology Center (CRTC) is an innovative independent 501(c)(3) non-profit corporation, whose mission is to inspire and grow the global composite recycling community through innovation in technology and manufacturing, that transforms carbon fiber scrap into products that positively impact people’s lives and our environment. Since carbon fiber is stronger than steel at one third the weight, the product applications in segments like transportation, aerospace and high performance sporting goods are boundless. The CRTC is accomplishing its mission by providing direct product manufacturing and technical design services, as well as by making low-cost recycled carbon fiber feedstock available for other manufacturers to utilize. The CRTC is supported through commitments from the Port of Port Angeles, with infrastructure investment from partners at the US Department of Commerce-Economic Development Administration (EDA), a grant from the EDA i6 Regional Innovation Strategies Program (RIS), WA State’s Clean Energy Fund, Clallam County, and the City of Port Angeles. Find out more at www.compositerecycling.org The CRTC campus also houses Peninsula College’s Advanced Manufacturing-Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with the CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. Learn more at www.pencol.edu/composites PORT ANGELES, Washington (February 09, 2018) – Over 50 million pounds of carbon fiber scrap goes into landfill globally each year. The Composite Recycling Technology Center (CRTC) in Port Angeles, WA is working to find unique and creative ways to keep carbon fiber scrap out of landfill and to create jobs in an economically distressed area. With several new carbon-fiber products ready for rollout, the CRTC needs to add at least 12 more production team members in 2018.

Fortunately, on the other side of the building, Peninsula College is training a workforce that is already getting hands-on experience with these aerospace-grade materials. The college’s Advanced Manufacturing and Composites Program shares a location with the CRTC and this close proximity is proving beneficial to both parties. As a part of the CRTC’s rapid expansion efforts, the CRTC and the Institute for Advanced Composite Manufacturing Innovation (IACMI) have selected Adam Jordan from Peninsula College for an IACMI Internship with the CRTC. “This is an exciting honor and having the internship at the same location as the college program is incredibly convenient as it allows me to better balance my school schedule with valuable workplace experience,” said Jordan. In its third year, the IACMI internship program provides students with hands-on industry project experiences and the opportunity to learn from our nation’s top advanced composite manufacturing experts in academia and industry. “The coupling of academic knowledge with field experiences in innovative, impactful projects such as composite recycling are an important part of our workforce strategy. Collaborating with the CRTC and Peninsula College to provide these experiences provides unique opportunities to students and significant value to the partners who often look at the program as a long term recruitment tool for high caliber employee talent.”, said Joannie Harmon Heath, IACMI Workforce Manager. Jordan is new to the Peninsula, having relocated from North Carolina recently with his family. After serving as a stay-at-home dad for the last five years, he is now following his dream of building an airplane. A substantial background in information technology has given him an attention to detail that he feels transfers well into working with composites. “We are delighted to see Adam Jordan selected for the IACMI Internship and know that he will do a great job to help advance the fine work that is being done by the CRTC to repurpose carbon fiber scrap, and enable low-cost and lower energy materials to help achieve IACMI’s goals.”, said Kelly Visconti, Technology Manager - Advanced Manufacturing Office at U.S. Department of Energy. “Adam has been a great addition to the CRTC team and really solidifies the value of having the Peninsula College Advanced Manufacturing program on site,” said Emily Dexter, people operations and communications manager for the CRTC. “Both organizations win in this situation. The students get real-world experience in a state-of-the-art educational facility, and the CRTC gets a well-educated and trained workforce.” For more information, contact Emily Dexter at [email protected] PORT ANGELES, Washington (January 5, 2018) - While being laser focused on prototype development, the Composite Recycling Technology Center had an entirely different project in development that involved no carbon fiber – new cabinets for the Port Angeles Salvation Army. The agency has a great food pantry but lacked storage for other relief items. As a community service project, the CRTC teamed up with Nathan Saxe of Twisted Elm Woodworking and Julian Lamarche of Mervin Manufacturing, to build and install new wood cabinets. “The CRTC truly admires all the work the Salvation Army does for our community,” said David Walter, CEO of the CRTC. “The daily care and support they provide to those in need is really outstanding and I know the meals they provide twice a day mean a lot. It was definitely our privilege to give a hand up by providing them with some added storage space.” The Salvation Army serves as a resource for the Port Angeles community, fulfilling basic human needs such as, food, warmth, shelter and safety, to those who are vulnerable and less able to help themselves. The agency served dinner to more than 200 people over the Thanksgiving and Christmas holidays. CRTC employees purchased wood for the new cabinets with help from Lamarche and Mervin Manufacturing, and cabinet construction by Saxe. The CRTC team then sanded, routed, installed cabinet doors and completed the installation in the designated space. “It is always entertaining to watch our team of Engineers come up with the best, most efficient way of doing things, even when it’s cabinet door handles. They truly are brilliant and a well-functioning team” said Emily Dexter, People Operations Manager of the CRTC. Salvation Army Major Ron Wehnau thanked the CRTC and other volunteers for their service to the agency. “We cannot thank the CRTC team enough for all the work they did for us,” Wehnau said. “The cabinets came out beautiful and the added storage space is a real blessing. It will be put to immediate use to store clothes and personal care products to truly help those in need.” Salvation Army of Port Angeles currently needs non-perishable food items, which can be delivered directly to 206 S. Peabody St, Port Angeles, WA 98362. They also accept donations online to directly support the community. Donations are tax-deductible as allowed by law. For more information on Salvation Army of Port Angeles, contact Majors Ron & Barbara Wehnau at (360) 452-7679 or [email protected] For more information on the Composite Recycling Technology Center, contact Emily Dexter at (360) 819-1204 or [email protected] ###  PORT ANGELES, WA – The Composite Recycling Technology Center has appointed Nobuyuki Odagiri to its Board of Directors. New membership and expansion of the nonprofit center’s board marks a significant milestone for the fast-growing organization, a pioneer in the reuse and remanufacturing of advanced materials. Nobuyuki Odagiri serves as Vice President and Senior Technical Fellow for Toray Composite Materials America, Inc., (CMA) of Tacoma, a longtime leader in the advanced materials industry. Odagiri-san has held numerous leadership positions during his 36-year career with the company, and been responsible for the overall management of Toray CMA operations including setting strategy as well as the Research & Development of Carbon Fiber Reinforced Composite Technologies. He has broad leadership experience and significant expertise in polymer synthesis and design, matrix resin design, and composite material design and fabrication. “We are delighted to have Odagiri-san join the Board,” said Anson Fatland, CRTC Board Chair. “He is a person of very high character combined with exceptional technical knowledge and really brings outstanding skills and abilities to the team. We know he will be a great asset to the CRTC organization as we drive hard and prepare for significant growth.” From its new, state-of-the-art facility at the Port of Port Angeles, the CRTC has pioneered the recycling and reuse of tons of uncured carbon fiber composite scrap – byproducts of aerospace manufacturing and assembly – materials that would otherwise go to landfills. An estimated 50 million pounds of carbon fiber scrap are produced annually, with approximately 2 million pounds per year produced in Washington State. With the expansion of regional manufacturing, this volume is expected to double over the next five to eight years. The mission of the CRTC is to inspire and grow the global composite recycling community through innovation in technology and manufacturing that transforms carbon fiber scrap into products that positively impact people’s lives and our environment. For its technological innovation and new market creation, CRTC earned the Silver Award for Sustainability from Seattle Business Magazine in 2017. The company has created 16 jobs and more than $3 million in new economic activity over the past year, garnering a 2016 Award of Excellence from the Clallam County Economic Development Corporation. Funding for the CRTC recycling facility and campus was provided by the Port of Port Angeles, the U.S. Economic Development Administration, the Washington State Department of Commerce, the Clallam County Opportunity Fund and the City of Port Angeles. The CRTC campus also houses Peninsula College’s Advanced Manufacturing Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. About Toray Composite Materials: Toray Composite Materials America, Inc. was formed in 2017 following the merger of Toray Composites (America), Inc. and Toray Carbon Fibers America, Inc., pioneers and longtime leaders in the advanced materials industry. CMA’s Tacoma plant was established in 1992 – incorporated in Pierce County, and located adjacent to Boeing’s Composite Manufacturing Center – enabling an efficient supply stream of Toray’s carbon fiber composite materials to the state’s aerospace industry. Toray’s advanced carbon fiber composite materials are now incorporated into the Boeing 777 and 787 primary structures and will be used on the new 777X wing. CMA’s Tacoma plant, a major exporter from Washington State, supplies a diverse customer base both domestically and internationally. For more information on the CRTC: www.compositerecycling.org For more information on the Toray CMA: www.toraycma.com ###  Left to right: CRTC Chief Executive Officer David Walter, CRTC Fellow and VP of Innovation Geoffrey Wood, U.S. Rep. Derek Kilmer, Washington State Department of Commerce Clean Energy Sector Lead Brian Young, and Loren Lyon, President and Center Director of Impact Washington stand together around the seatback preform on August 8, 2017. The Composite Recycling Technology Center and ELG Carbon Fibre Ltd of the

UK jointly demonstrated the manufacture of an automotive seatback made from recycled carbon fiber composite, at the Automotive Lightweight Materials Summit in Detroit, Mich., on Aug. 22-24, 2017. The tooling was supplied in partnership with the Institute for Advanced Composite Manufacturing Innovation (IACMI) of Knoxville, Tenn. The goal of the project was to demonstrate manufacturability of the materials, to test flow and compaction into the various features, and to provide samples for non-destructive and destructive testing. The project successfully addressed all issues to develop final prototypes. It will lead the way forward to entering production in automotive interiors with fast-cycle molding of recycled carbon fiber/thermoplastic materials at highly competitive costing. ELG, CRTC, and IACMI look forward to the next steps in the development efforts and pursuing production opportunities in high-volume applications. “This is a very exciting project and I am very proud of the entire team who worked hard to turn this seat from a vision into reality,” said David Walter, CRTC CEO. “The close collaboration with the team from IACMI and ELG made this project a big success.” The bucket-style seatback is approximately 24-inches high and 19-inches wide, with side flanges of nearly 5-inches at their deepest. It utilized 1.3 kg of ELG’s Carbiso TM PA6 60% SM45D. The recycled fiber/nylon 6 resin was molded at CRTC in a hot compression cycle at 435 F, using their Wabash/MPI 300-ton hot-platen press. The seatback was molded in IACMI’s aluminum tool that was previously developed for a pre-production prototype evaluation project. From its new, state-of-the-art facility leased from the Port of Port Angeles, the CRTC has pioneered the recycling and reuse of tons of uncured carbon fiber composite scrap that would otherwise go to landfills. The CRTC’s focus is to create jobs and drive economic development in Clallam County. About 50 million pounds of carbon fiber scrap are produced annually, with approximately 2 million pounds per year produced in Washington state – a volume expected to double over the next five to eight years, with the expansion of regional manufacturing. Under a new contract with IACMI, the CRTC will pioneer ways to automate processing of this scrap and remanufacture it into new consumer products. This technology breakthrough is essential so carbon fiber scrap can be processed in high volumes, fulfilling the enormous potential for energy savings and carbon reduction and creating a global composites recycling industry. For its technological innovation and new market creation, CRTC earned the Silver Award for Sustainability from Seattle Business Magazine in 2017. The company has created 16 jobs and more than $3 million in new economic activity over the past year, garnering a 2016 Award of Excellence from the Clallam County Economic Development Corporation. The CRTC has a multi-faceted agreement with Toray Composite Materials America for scrap carbon fiber supply and materials development, and continues to work very collaboratively with this strategic partner. Funding for the CRTC recycling facility and campus was provided by the Port of Port Angeles, the U.S. Economic Development Administration, the Washington State Department of Commerce, the Clallam County Opportunity Fund and the City of Port Angeles. The CRTC campus also houses Peninsula College’s Advanced Manufacturing Composite Technology program with classrooms, offices, and lab facilities. The program gives students hands-on training in advanced materials recycling and remanufacturing techniques. Co-location with CRTC provides students with unequaled opportunities for internships, manufacturing and R&D experience, and exposure to production operations. For more information contact: David Walter, 360-819-1203, [email protected] For more information on the CRTC: www.compositerecycling.org |

RSS Feed

RSS Feed